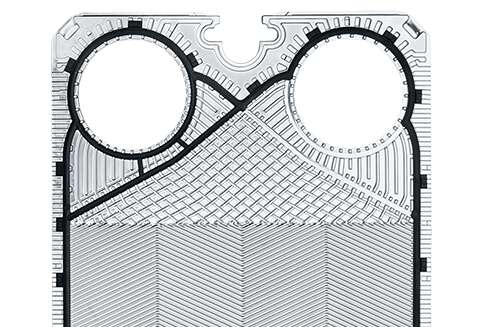

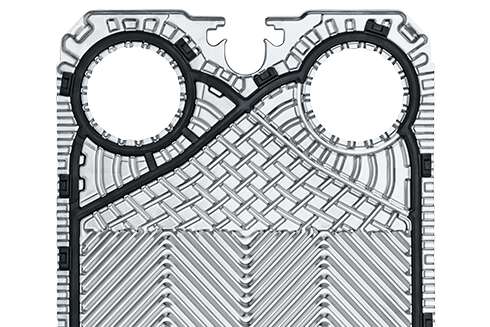

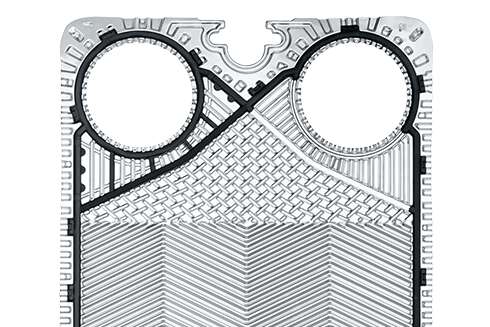

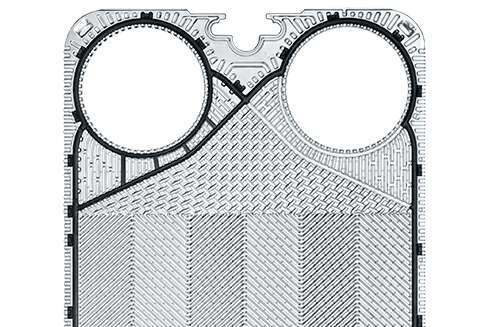

Our gasketed plate heat exchangers combine passion, scientific curiosity and technological expertise. The facts: High efficiency at low operating costs, versatile application possibilities with lower investment costs and maximum flexibility. Our efforts to continuously develop the gasketed plate heat exchanger-series further are aimed at meeting your thermodynamic and hydraulic performance needs and to ensure maximum economic efficiency.

Gasketed Plate Heat Exchanger

IN ADDITION TO THESE COMMON APPLICATIONS, OUR GASKETED PLATE HEAT EXCHANGERS ARE ALSO SUITABLE FOR:

- chemical process cooling

- media containing fibres and solids (e.g., in the sugar and paper industry)

- highly viscous media (e.g., dairy and other food products)

- healthy drinking water treatment and purification

- secure cooling for power plants with river or seawater

- demanding climate control solutions (e.g., for data centres)

- condensation or evaporation (e.g.,in refrigeration, sugar or chemical industries)